Crm software for manufacturing industry – The manufacturing industry is a complex ecosystem demanding efficient processes and streamlined communication. Customer Relationship Management (CRM) software offers a powerful solution to these challenges, providing a centralized platform to manage customer interactions, track projects, and optimize operations. This detailed guide explores the vital role of CRM in manufacturing, outlining its key features, benefits, and considerations for successful implementation.

Understanding the Unique Needs of Manufacturing CRMs

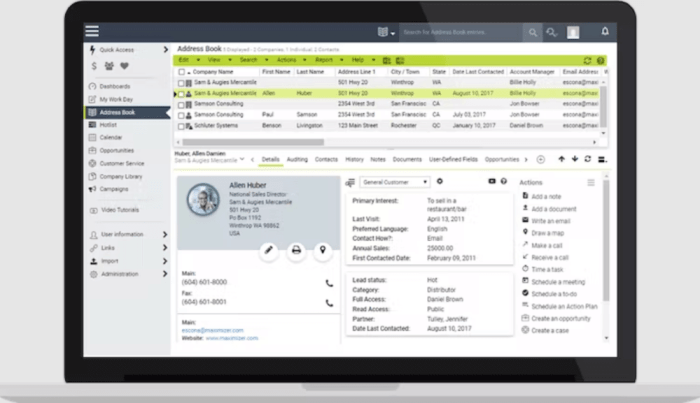

Unlike other industries, manufacturing requires a CRM system capable of handling intricate production processes, complex supply chains, and specialized customer requirements. A robust manufacturing CRM must integrate seamlessly with existing Enterprise Resource Planning (ERP) systems and offer functionalities tailored to the unique aspects of the industry. This includes features for managing inventory, tracking production orders, and facilitating communication across various departments, from sales and marketing to production and customer service.

Key Features of a Manufacturing CRM, Crm software for manufacturing industry

- Lead Management & Sales Pipeline: Effective lead tracking, qualification, and nurturing are crucial. The CRM should offer tools to manage the entire sales cycle, from initial contact to final sale.

- Project Management & Order Tracking: Manufacturing projects often involve multiple stages and stakeholders. A CRM should facilitate project tracking, resource allocation, and timely order fulfillment. This includes features for scheduling, progress monitoring, and issue resolution.

- Inventory Management: Real-time inventory tracking and management are essential for efficient production and timely delivery. Integration with warehouse management systems (WMS) is highly beneficial.

- Supply Chain Management: Managing relationships with suppliers and distributors is critical. The CRM should facilitate communication, collaboration, and tracking of materials throughout the supply chain.

- Customer Service & Support: Providing excellent customer service is crucial for customer retention. The CRM should offer tools for managing customer inquiries, resolving issues, and tracking service requests.

- Reporting & Analytics: Data-driven decision-making is vital in manufacturing. The CRM should provide comprehensive reporting and analytics capabilities to track key performance indicators (KPIs) and identify areas for improvement.

- Integration with ERP Systems: Seamless integration with existing ERP systems is essential to avoid data silos and ensure data consistency across the organization. This enables a holistic view of the business.

- Customization & Scalability: The CRM should be customizable to meet the specific needs of the manufacturing business and scalable to accommodate growth.

Benefits of Implementing a CRM in Manufacturing

Implementing a CRM system offers numerous benefits for manufacturers, leading to increased efficiency, improved customer relationships, and enhanced profitability. These benefits include:

- Improved Customer Satisfaction: By centralizing customer information and improving communication, manufacturers can provide better service and build stronger customer relationships.

- Increased Sales & Revenue: Effective lead management and sales pipeline tracking can lead to increased sales conversion rates and revenue growth.

- Enhanced Operational Efficiency: Streamlined processes and improved communication can significantly improve operational efficiency and reduce costs.

- Better Inventory Management: Real-time inventory tracking helps prevent stockouts and overstocking, optimizing inventory levels and reducing costs.

- Improved Supply Chain Management: Better communication and collaboration with suppliers and distributors can improve supply chain efficiency and reduce lead times.

- Data-Driven Decision Making: Comprehensive reporting and analytics provide valuable insights into business performance, enabling data-driven decision-making.

- Stronger Customer Relationships: Personalized communication and proactive customer service foster stronger customer relationships and improve loyalty.

Choosing the Right CRM for Your Manufacturing Business

Selecting the appropriate CRM system is crucial for success. Consider the following factors:

- Business Size and Complexity: Choose a system that scales with your business growth and accommodates your specific needs.

- Budget: Consider the cost of the software, implementation, and ongoing maintenance.

- Integration Capabilities: Ensure the CRM integrates seamlessly with your existing ERP and other systems.

- User-Friendliness: Select a system that is easy to use and adopt by your team.

- Customization Options: Ensure the system can be customized to meet your specific requirements.

- Vendor Support: Choose a vendor with excellent customer support and a proven track record.

Examples of CRM Software for Manufacturing

Several CRM platforms cater specifically to the manufacturing industry. Research and compare different options based on your needs and budget. Some popular examples include:

- Salesforce Manufacturing Cloud: A comprehensive platform offering industry-specific features.

- Microsoft Dynamics 365 for Finance and Operations: A powerful ERP system with strong CRM capabilities.

- Oracle Siebel CRM: A robust CRM solution suitable for large manufacturing enterprises.

- SAP CRM: Integrated with SAP’s ERP solutions, offering a complete business management suite.

- Infor CloudSuite Industrial (SyteLine): A comprehensive ERP and CRM solution specifically designed for discrete and process manufacturers.

Remember to thoroughly evaluate each platform’s features, pricing, and integration capabilities before making a decision. Consider seeking professional advice from a CRM consultant to ensure you select the best fit for your business.

Source: method.me

Frequently Asked Questions (FAQ)

- Q: What is the average cost of a manufacturing CRM? A: The cost varies significantly depending on the chosen software, features, number of users, and implementation services. Expect a range from a few hundred dollars per month for smaller businesses to tens of thousands for large enterprises.

- Q: How long does it take to implement a manufacturing CRM? A: Implementation time depends on the complexity of the system, data migration requirements, and user training. It can range from a few weeks to several months.

- Q: What are the key metrics to track after implementing a manufacturing CRM? A: Key metrics include sales conversion rates, customer satisfaction scores, order fulfillment time, inventory turnover rate, and supply chain efficiency.

- Q: Can a CRM integrate with my existing ERP system? A: Most modern CRM systems offer robust integration capabilities with various ERP systems. However, ensure compatibility before selecting a CRM.

- Q: What is the return on investment (ROI) of a manufacturing CRM? A: The ROI varies depending on the specific implementation and business goals. However, improved efficiency, increased sales, and enhanced customer satisfaction contribute to a positive ROI over time.

Conclusion

Implementing a CRM system is a strategic investment for manufacturers seeking to improve efficiency, enhance customer relationships, and drive growth. By carefully considering the specific needs of your business and selecting the right CRM solution, you can unlock the full potential of your operations and gain a competitive edge in today’s dynamic market. Remember to prioritize seamless integration, user-friendliness, and ongoing support to ensure a successful implementation and maximize your return on investment.

Source: techunfolded.com

References: Crm Software For Manufacturing Industry

- Salesforce Manufacturing Cloud

- Microsoft Dynamics 365 for Finance and Operations

- Oracle Siebel CRM

- (Add other relevant links as needed)

Call to Action

Ready to transform your manufacturing business with a powerful CRM? Contact us today for a free consultation and let’s discuss how we can help you optimize your operations and achieve your business goals.

Top FAQs

What are the key features to look for in a manufacturing CRM?

Key features include inventory management integration, production scheduling tools, project management capabilities, and robust reporting and analytics dashboards tailored to manufacturing metrics.

How much does CRM software for manufacturing typically cost?

Pricing varies widely depending on the vendor, features, and number of users. Expect a range from subscription-based models with monthly fees to larger upfront investments for enterprise-level solutions. It’s best to obtain quotes from multiple vendors.

How long does it take to implement a manufacturing CRM?

Implementation timelines vary significantly based on the complexity of the system, the size of the company, and the level of customization required. Expect a process ranging from several weeks to several months.

Can CRM software integrate with existing ERP systems?

Yes, many CRM systems offer robust integration capabilities with existing Enterprise Resource Planning (ERP) systems, allowing for seamless data flow and a unified view of business operations.

What are the potential challenges of implementing a CRM in a manufacturing setting?

Challenges can include data migration complexities, user adoption issues, resistance to change within the organization, and the need for thorough training and ongoing support.